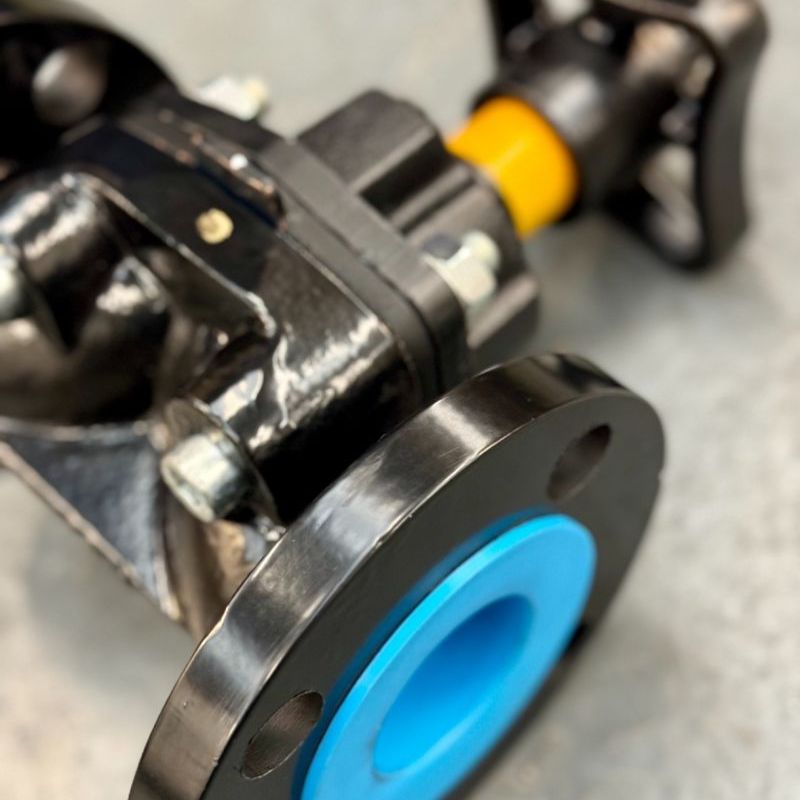

AUSTRALIAN Diaphragm Valves

Excellent Flow Control Precision

Abrasion and Corrosion Resistance

Total Low Cost of Ownership

Benefits of a Diaphragm Valve

HYGIENIC DESIGN

By prioritizing hygienic design it mitigates the threat of contamination – safeguarding your products, brand reputation, and consumer safety

MATERIAL SELECTION

Select from a variety of materials, such as metals, rubber, polymers, and internal components, all specifically designed to withstand extreme temperatures without deformation or loss of integrity.

INNOVATIVE ASSEMBLY

Diaphragm valves that integrates to your processess using Fail-safe mechanism it’s designed to close automatically if air or power fails, providing an extra layer of safety.

BUBBLE TIGHT SHUT OFF

Diaphragm Valves focuses on leak prevention and sterility. Its function relies on a flexible diaphragm that presses against a seat, regulating flow and creating a tight seal.

PROCESS CONTROL SELECTION

Choose a powerful partner in streamlining process control in a variety of industries. Optimizing flow regulation is crucial for maximizing efficiency and resource conservation.

LOW MAINTENANCE

Simplify your maintenance processes with diaphragm valves that enable quick and secure isolation of system sections, reducing downtime while maintaining effective control.

TYPES

BODY

PARTS

Why should you use a Diaphragm Valve?

ETFE-lined diaphragm valves are one of the preferred choice in so many critical applications. Its ability to provide precise fluid control while offering unmatched chemical resistance and durability.

Diaphragm valves, particularly the weir-type, provide exceptional flow control and leak-proof sealing, essential in industries where fluid integrity and operational reliability are critical.

Diaphragm valves use a flexible diaphragm to regulate the flow of media, offering a combination of tight sealing, easy maintenance, and excellent resistance to contamination.

Structure is simple, that being said it can be disassembled in case there’s a need for replacement of the diaphragm or other parts.

With the chemical resistance of a diaphragm valve specifically stainless steel or plastic-lined, it is possible to handle hazardous chemicals and radioactive fluids with ease.

Are diaphragm valves sanitary? Absolutely. The smooth, flexible diaphragm effectively isolates the process media from the valve body and actuator, preventing the formation of pockets or crevices where contaminants could accumulate.